Description

A simple and effective solution to avoid galvanic torque.

Information

- Max 10bar

- Seal threaded connections with Loctite 55 or adhesive

Galvanic torques

Corrosion upon contact of two different metals in the same water;

here a galvanic torque (electrolysis) arises. The "strong" metal (copper/brass)

will dissolve the "weak" metal.

-> In a sanitary installation, you can use galvanised pipes first and then copper pipes, never the other way round!

->

At the outlet of a stainless steel boiler, it is therefore advisable to install this fitting.

If copper has been used upstream (in a riser pipe in an apartment building, for example), and you continue upstairs with galvanised pipe, the water containing copper (copper ions) will run through the galvanised pipe, and if there is a stagnation, the more noble metal (the copper ions) will corrode the less noble metal (the thin zinc protective layer of the galvanised pipe). Once this zinc layer is affected, the underlying steel (iron) will suffer the same fate.

With central heating installations you get the same corrosion phenomena (e.g.: the copper pipe, which gives off charged copper ions, will corrode the steel (iron) of the radiators), but because a central heating installation is a closed circuit, and all oxygen in the water is used up after some time, the corrosion will stop after a few weeks.

The water binds with the steel of the radiator and becomes dark brown to black: magnite formation. This is very bad for circulation pumps and heat output of the radiators. Avoid this with a dirt and air separator!

Steel pipes and steel radiators are also affected, because the oxygen-rich water extracts iron ions from the steel; these will bind with the oxygen and form magnetite. This corrosion continues until all oxygen is used up. When the system is put into operation, and therefore when it is filled for the first time, this can take several weeks.

That is why corrosion in a heating installation is usually to be sought in a connection that is not oxygen-tight.

Even with slight leaks, one will sometimes have to add water that contains oxygen and this will again initiate corrosion.

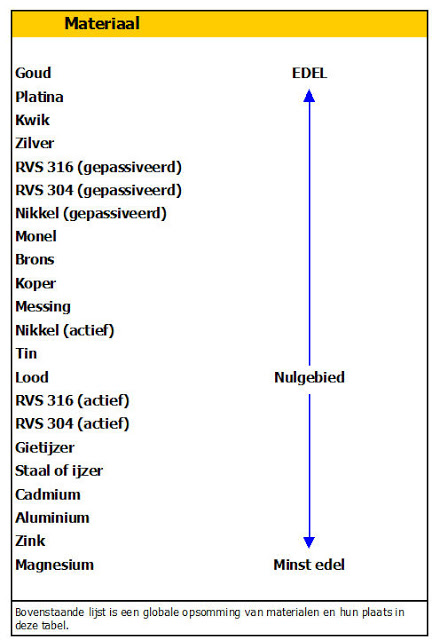

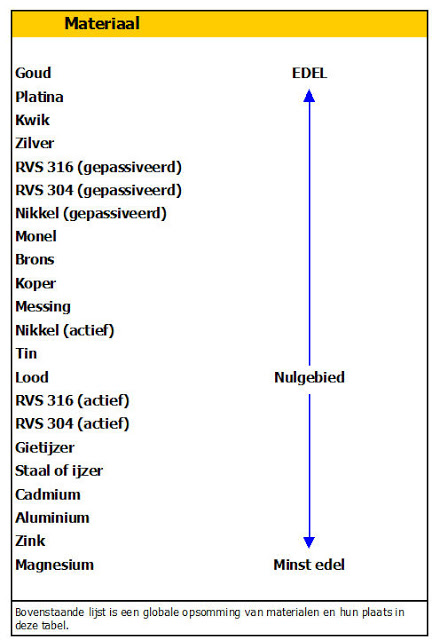

The table below

You should never take the following materials in opposite directions. If you do, you must use our anti-electrolysis solution.